by Dean Mance | Oct 14, 2014 | Dodgy Installations, Keep Your Family Safe, Uncategorized

We had a call from a guy who had installed his own exhaust fan and couldn’t get it to work.

The client had been to a major hardware store and purchased a fan, some cable and a switch. He cut a hole in the ceiling and fitted the fan, connected the wire to the fan and ran the cable down the wall and connected it to the switch.

He then stood in his bathroom, flicking the switch and wondering why the fan wouldn’t work. It didn’t work because the cable only ran between the fan and the switch, there was no connection to any power circuit.

The client was extremely embarrassed when we explained the problem and in this case there was no immediate danger as there was no power connection involved.

Although it’s an amusing story it highlights the lack of understanding of the average handyman (yes, it’s always a man) when dealing with electrical work.

Do ItYourself electrical work is always non compliant in some way and is often little more than a trap set to catch the tradesman who is unfortunate enough to follow up such work.

Compared to the cost of losing your home in a fire and having no insurance, the small amount of money this client tried to save would be totally insignificant.

Those most at risk from DIY electrical work are the family members who live in the home. Doing your own electrical work is illegal. Play it safe and get it done by a properly qualified person.

If you have any doubts or concerns about work that may have been carried out at your property please give us a call on 6331 4711 or send us an email and we’d be happy to do a quick check and advise on the condition and safety of your electrical installation.

by Dean Mance | Sep 23, 2014 | Dodgy Installations, Keep Your Family Safe, Solar Power

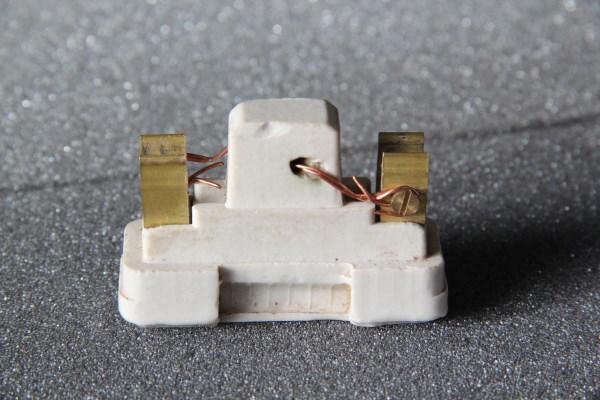

This is what’s left of a defective DC isolation switch on the roof of a solar installation we attended recently.

The picture below shows what it used to look like.

This particular brand of isolation switch was subject to an Australia wide total recall, due to the possibility of it catching fire.

So far, four brands of imported DC isolators have been recalled after causing similar problems.

The experience of solar clients has varied, with some having the faulty parts replaced quickly at no charge, and some finding that no-one wants to take responsibility for rectifying the faults.

Two of the companies that imported the isolators have folded, leaving wholesalers and installers holding the bag.

This unfortunate situation highlights the importance of using a reputable, local installer for your solar job so you have someone you can talk to face to face if something goes wrong.

If you did experience a problem, would you rather be phoning a long established, local business, or a mainland call centre?

Fortunately, Mance Electrical has never used any of the recalled isolators, which were more commonly used by those solar sales companies that advertise heavily on TV.

Our solar panels, inverters and isolators are supplied by Energy Aware and they only use quality products from Trina, Simax, SMA, Canadian Solar, Suntech and other quality manufacturers.

Click here to check out the Energy Aware website or give us a call on 6331 4711 for free advice, free quotes and answers to all your questions about solar panel installations.

Like our Facebook page to make sure you keep up with the latest info on all things electrical.

by Dean Mance | Aug 28, 2014 | Dodgy Installations, Keep Your Family Safe, Uncategorized

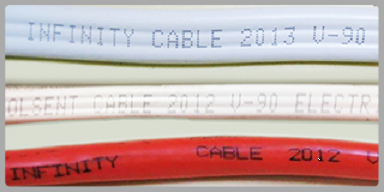

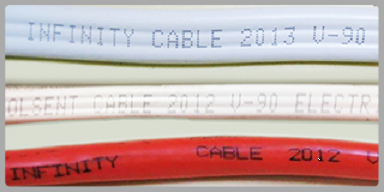

The ACCC has announced a cable recall of Infinity brand electrical cables due to the fire and electrocution risks posed by the sub-standard product.

The poor quality plastic insulation deteriorates rapidly, becoming brittle and susceptible to falling apart if disturbed.

Mance Electrical has never purchased this brand of cable so our clients can be assured there is none of this potentially dangerous product installed in their premises.

The cable was supplied through various hardware outlets between January and October 2013 and could have been purchased by other electricicans or even home owners themselves.

(That’s a separate issue in itself – It’s illegal to do your own electrical work, why can anybody just walk into a hardware store and buy a power point and a few meters of cable?)

Mance Electrical purchases cable from electrical wholesalers who have never stocked this particular brand.

If you are concerned that you may have some of this cable in your home or business, call your electrician and ask them to check their records, or arrange a visit to check the existing installation. There is probably only a small amount of this cable installed in Tasmania, however if you are affected, you may be able to claim the cost of repair or replacement from the cable supplier.

For further information, see the ACCC website, which has a frequently asked questions section on Infinity Cables, or give us a quick call on 6331 4711.

by Dean Mance | Jul 5, 2014 | Common Repairs, Dodgy Installations, Keep Your Family Safe

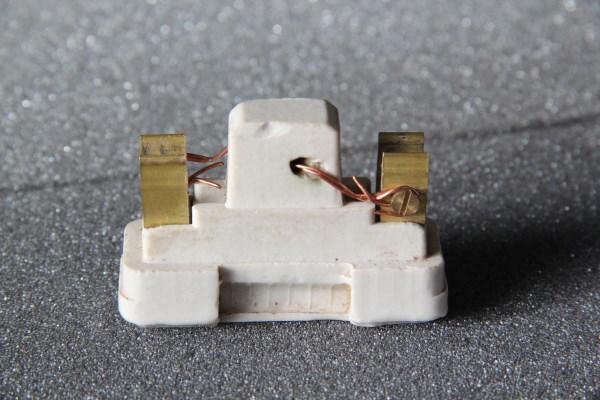

This is dangerous and could burn your house down.

Obviously someone was having trouble with a fuse repeatedly blowing so instead of putting in standard 16 amp fuse wire they used a doubled up strand of copper wire that is probably good for about 150 amps!

It may have stopped the fuse blowing, but could have caused much more serious problems.

The fuse is designed to be the weakest link in the circuit, at a known location. When a fuse blows it is an indication something is wrong.

If the problem is due to overloading, maybe from too many heaters on one circuit, the fuse wire will just quietly melt apart.

If the problem is caused by a short circuit fault the fuse will go off with a bang.

Either way, if you beef up the fuse wire so it can’t blow then another part of your wiring becomes the weakest link, but you won’t know which part.

If the fuse can’t blow then maybe the wiring in that dodgy old light fitting, or the loose connection in the wall cavity will overheat. Maybe get hot enough to start a fire.

Fuses blow for a reason and the reason needs to be discovered and the fault fixed.

If you are having fuse problems you can give us a call at the workshop on 6331 4711 for some helpful advice or arrange for one of our tradesmen to visit and fix the problem. This service is also available after hours, seven days a week.

Make sure you check our next blog post where we will discuss the safe way to deal with blown fuses.

by Dean Mance | Jun 29, 2014 | Dodgy Installations, Keep Your Family Safe, Save Money

One of our clients has to make this choice every day.

If they want to run their oven they have to go outside to the switchboard and turn off the hot water first.

If the hot water is not turned off, the main circuit breaker will overload and trip, shutting off all power to the house.

How did they get into this crazy situation?

It happened because they got a cheap heat pump installation. The mains cables to the house are a very small size and before adding extra heating the mains cables should have been replaced with larger cables.

The contractor who installed the heat pump bypassed the requirement to upgrade the mains by fitting a 32 amp load limiting circuit breaker to the switchboard.

The circuit breaker protects the cables by shutting off when the total load drawn by all the appliances in the house exceeds 32 amps.

An oven can draw up to 32 amps on its own, so they probably couldn’t run a heater and the oven together, or a heater and hot water at the same time either.

It is legal and the work was carried out according to the wiring rules, but it’s not a quality result for the client.

Maybe the details weren’t sufficiently explained to the client before the heat pump was installed, or maybe they just wanted the cheapest price, no matter what.

We will soon be replacing the mains cables and that will solve the problem. No more running out to the fuse box with a torch, flicking switches on and off.

It probably would have cost less to get it all done when the heat pump was installed.

It’s another example of why the cheapest price is not usually the best job, and highlights the importance of getting good advice before starting major electrical work on your home.

For free advice and quotes on all mains cables upgrades, in Launceston and surrounding areas, phone Mance Electrical on 6331 4711.

by Dean Mance | Jun 10, 2014 | Common Repairs, Dodgy Installations, Keep Your Family Safe

The ceiling space of your home could be a dangerous place…

Old wiring, rodent damage or poor installation could all spell disaster for the home handyman.

Maybe you want to install some insulation, check for a water leak or remove the dead animal causing that awful smell in your roof – whatever the reason, you should turn off all the power to your home, before getting into the roof space.

In older homes the main hazard is deteriorated VIR, rubber or lead wiring. In newer homes the hazard is incompetence and shortcuts by dodgy tradesmen. Rodent damage can also expose live wires and connections.

Insulation often covers electrical components such as wiring, junction boxes and light fittings. While crawling around in your roof space, its easy to accidentally touch a live part from damaged or poorly installed electrical equipment.

Problems we have found in roof spaces recently include live bare wires, exposed wiring from rodent damage, water damaged light points, crumbling rubber cable, light fittings not correctly earthed, and dangerous home handyman wiring.

Play it safe and turn off the main switch at your switchboard and use a battery operated torch for illumination while working in the roof space.

If in doubt, give us a call on 6331 4711.